Case Study Schofer Pforzheim

Application examples:

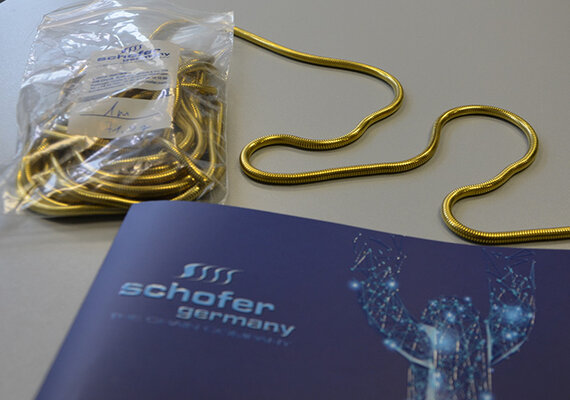

- Drying of end caps for bracelets

- Caps are made of stainless steel and are cleaned prior to drying

- Also suitable for drying chains (including some gold-plated ones)

Procedure:

- Phase 1: Rack is filled with wet caps and transferred to the chamber, VD 53 starts generating vacuum

- Phase 2: Drying process takes place at 30 °C

- Phase 3: The second pressure drop occurs, indicating that the drying process is complete. The dried caps can be removed.

- Drying takes up to 20 minutes

Customer requirements:

- Between 3,000 and 4,000 caps to be dried daily and up to 100,000 per month

- All moisture to be removed from jewelry

- No corrosion must occur

- Temperature range: 50 °C–70 °C

- Program-controlled drying monitoring with automatic ventilation at end of process

- Parts must not be scratched as they are being placed inside

Why BINDER?

The head of the design and product development department at Schofer in Pforzheim explains:

BINDER solutions in the form of a vacuum drying chamber for non-flammable solvents:

- Fast, gentle drying

- Optimum heat transfer through large thermal conducting plates

- Safe work thanks to proven safety concept

- Also optionally available as a modular complete system with vacuum pump and pump chambe

- Internal data logger, measured values can be read out in open format via USB

- At least one aluminum expansion rack, can be custom-positioned

- Space-saving in laboratory environments and quiet running

- Absolute reliability coupled with low power consumption