With a temperature range of +5°C to +60°C

Show product

A photostability test chamber is a climate chamber with light which generates defined light conditions in addition to temperature and humidity. Light climate chambers are used for stability testing to determine the shelf life of products. They are used in different sectors, such as the pharmaceutical, cosmetics, and food industries. Photostability tests examine the influence of temperature, humidity, and exposure to light on a product. The test materials are first stored in a climate chamber under defined conditions (constant temperature, constant relative humidity, and constant light intensity) for a specified period of time before the shelf life is checked. The test materials are exposed to light using both visible light (VIS) and ultraviolet radiation (UV), which is considerably more aggressive than VIS radiation.

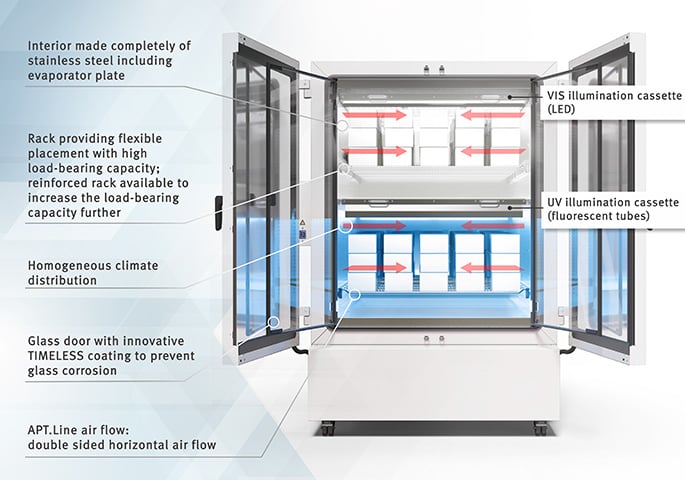

A light climate chamber features an interior (usable space) in which the required light and climate conditions are generated and maintained over a predefined period of time.

The test materials are sequentially irradiated with UV light and VIS light in the usable space. When using the light-dosage measurement option, the corresponding light source is automatically switched off once the preset light dosage has been reached.

The UV fluorescent tube technology ensures standard-compliant irradiation with the specified standard spectrum according to ICH guideline Q1B.

The VIS light unit with three different types of LED perfectly simulates daylight according to standardized light D65.

Extensive stability testing must be performed as part of the approval process for drugs. According to the guidelines from the ICH (International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use) the photostability of drugs must also be tested. The test materials are exposed to both visible light (VIS) and ultraviolet radiation (UV). If the drug proves to be sensitive to light during testing, the manufacturer must provide separate instructions for storage.

BINDER photostability test chambers ensure reproducible light and climate conditions as well as the perfect distribution of light, temperature, and humidity. The light systems used fulfill the requirements of ICH guideline Q1B, Option 2. They can be used to carry out a complete ICH photostability test in just three days.

In the food industry, shelf-life testing is carried out to determine the shelf life of a product under different storage conditions and therefore calculate the exact best-before date. To achieve meaningful results quickly, food manufacturers perform accelerated shelf-life testing (ASLT). This involves using a constant climate chamber to simulate temperature, humidity, and light at predefined values. The test also evaluates changes in color (fading) which can be caused by exposure to light. The samples are stored at different temperatures, such as 20 °C, 30 °C, and 40 °C, and exposed to a defined light intensity. Finally, color loss is measured as changes in hue (ΔH) as a function of different time intervals. Chemical, microbiological, physical, and gustatory changes are measured at regular intervals and the best-before date of the products is established in this way.

In the pharmaceutical industry, the ICH Q1B guideline regulates stability testing under the influence of light.

The exact irradiation dose with both visible and UV light and complying with the light spectra specified in ICH Q1B is of crucial importance. BINDER photostability test chambers reliably meet these criteria.

With the aid of optional, network-enabled APT-COM GLP Edition software, the test parameters can be reliably recorded and documented according to Good Laboratory Practice (GLP) and in compliance with FDA Regulation 21 CFR Part 11.

You can read all about ICH photostability testing and everything to consider before purchasing a climate chamber in our whitepaper “Stability testing according to ICH Q1A (R2): Basics and technical solutions.”

For photostability tests according to ICH Q1B, the light sources and illuminance levels are crucial. The light spectra and illuminance doses are precisely specified. The visible light (VIS similar to ISO 10977 (1993)) must reach a VIS light dosage of at least 1.2 million lux hours and the near ultraviolet (320 nm to 400 nm) dosage must be at least 200 Wh/m². There are illumination cassettes providing flexible placement, so homogeneous light distribution is guaranteed in the interior. In terms of the irradiation by UV light, according to ICH guideline Q1B, a significant proportion of the UV radiation must be in the range of 320 to 360 nm as well as in range of 360 to 400 nm. The BINDER photostability test chambers meet this requirement in full.

A distinction is made between systems that use an illumination cassette for UV and VIS and those that use a separate UV illumination cassette and VIS illumination cassette. Separate illumination cassettes for VIS and UV light are used in the BINDER photostability test chambers. After half the test time, the samples are swapped and exposed to the other light source

The air movement is a constant climate chamber is crucial for climate homogeneity inside the unit. Only homogeneous climate conditions, both in terms of space and time, provide reliable results. Double-sided horizontal air flow allows for particularly homogeneous conditions. The air is extracted via a perforated rear wall and returned back into the usable space after reconditioning. The air is distributed evenly into the chamber via small perforations in the side walls and therefore flows evenly over the test materials from both sides.

When combined with the new ICH light modules, our latest generation of climate chambers become photostability test chambers.

The light spectra fulfill the requirements of ICH guideline Q1B, Option 2. Modern LED technology is used for visible light. However, the UVA range cannot be covered with the current LED technology in accordance with ICH, which explains the use of fluorescent tubes.

The irradiance levels are designed so that a complete test can be carried out in three days. The light intensities were deliberately limited to this level to avoid thermal effects during the photostability test.

The ICH light modules are available with or without light-dose control (LQC) and in two sizes. They can be combined with climate chambers from the KBF and KBF PRO series in sizes 260, 470, and 720. For ICH photostability tests without humidity, the light modules can be combined with units from the KB PRO series.

Light module ICH 260/470 or ICH-LQC 260/470

Light module ICH 260/470 or ICH-LQC 260/470

Light module ICH 720 or ICH-LQC 720

Light module ICH 260/470 or ICH-LQC 260/470

Light module ICH 260/470 or ICH-LQC 260/470

Light module ICH 720 or ICH-LQC 720

Light module ICH 260/470 or ICH-LQC 260/470

Light module ICH 260/470 or ICH-LQC 260/470

Light module ICH 720 or ICH-LQC 720